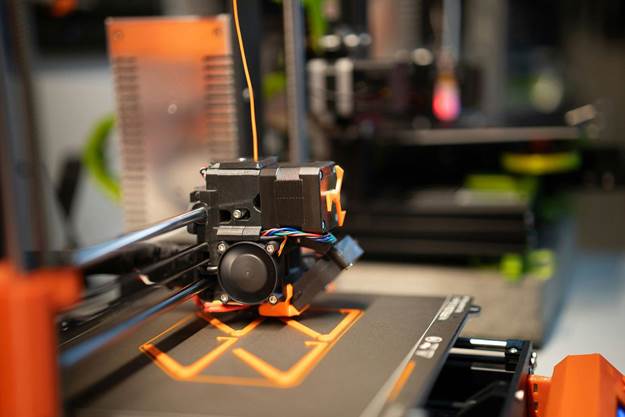

Here’s something that’ll grab your attention: manufacturers using 3D printing for actual industrial production doubled between 2018 and 2019. That wasn’t some fluke. It was the moment 3D printing in manufacturing graduated from cool prototyping toy to legitimate production workhorse. These days, companies are slashing lead times, pivoting on a dime when demand shifts, and cranking out custom parts without the headache of retooling entire production lines.

What you’re about to read is the full story, the timeline, the game-changing breakthroughs that made 3D printing for production real, and a no-nonsense framework to figure out if additive manufacturing production actually makes sense for your volume targets, quality demands, and bottom line.

Partnering for production success with Top 3D printing companies like RapidMade

Scaling from one-offs to repeatable production runs often hinges on partner selection, and Top 3D printing companies like RapidMade bring the disciplined processes and production infrastructure manufacturers need to succeed. RapidMade provides ISO 9001-certified, ITAR-registered additive manufacturing backed by in-house engineering teams, DfAM consultation, and production-grade finishing capabilities. Their 30,000 sq ft Portland operation handles everything from rapid prototyping through low-volume production with complete traceability and quality documentation.

When you’re vetting partners, request sample inspection reports, their process validation methodology, and repeatability data. Share performance specs, cosmetic zones, inspection requirements, and volume projections upfront to dodge expensive iteration cycles. As volumes scale, nail down repeatable pricing structures, batching strategies, and quality gates with clear KPIs: yield rates, lead time consistency, dimensional capability indices, and corrective action response times.

3D printing prototyping to 3D printing for production: the turning points that changed everything

You can’t appreciate where this tech sits today without rewinding to the moments that flipped it from a novelty into something credible so let’s walk through three distinct phases that rewrote the rules.

Prototype-only era (late 1980s–2000s): speed wins, performance lags

Those early machines? Great for eyeballing a concept. Awful for anything functional. Materials cracked under pressure, precision bounced around unpredictably, and build chambers were laughably small. Engineers leaned on 3D printing prototyping for quick form checks and design critiques never for parts that actually had to carry a load. The process simply wasn’t reliable enough for production stakes.

That said, there’s still a place for prototype-grade thinking. When you’re iterating fast on aesthetics or testing ergonomics before anyone cares about durability, speed crushes everything else.

Production credibility era (2010s): materials, machines, and metrology mature

Speed dominated early adoption, sure. But around 2010, something fundamental shifted materials science, machine precision, and quality systems finally grew up enough to meet production standards. Nylon powder-bed tech got way better. New resins hit the market. Metal LPBF delivered consistent outcomes. Software quit crashing. Traceability became a thing.

Here’s your litmus test for production-ready: locked-down process parameters, validated material certs, reliable vendor support, and documented repeatability data. Skip any of those? You’re still playing in the prototype sandbox.

Full-scale additive manufacturing production era (2020s): automation + digital workflows

Better materials and tighter machines weren’t enough on their own. True scale demanded one final ingredient: the automation, smart software, and integrated workflows that define modern additive manufacturing. Post-processing robots, intelligent queue systems, MES integration, faster print speeds all the puzzle pieces clicked. Suddenly, distributed manufacturing wasn’t just a buzzword anymore.

Production AM shines brightest when parts are geometrically complex, need customization, fall into low-to-mid volumes, or when traditional supply chains can’t keep pace. That’s your target zone.

Industrial 3D printing applications in manufacturing that moved beyond prototypes

Now that the tech evolution makes sense, let’s dig into where manufacturers are actually using production 3D printing and the logic they’re using to pick the right spots.

End-use components in regulated industries (aerospace, medical, automotive)

Aerospace folks print brackets, airflow ducts, and weight-optimized assemblies. Medical teams fabricate patient-matched implants. Auto engineers spin up tooling and niche-volume parts. Get this: in 2021, 72% of aerospace and defence prototyping relied on 3D printing that’s deep integration even before full-blown production takes over.Your must-haves: material certifications, batch traceability, inspection protocols, and a rock-solid validation approach. Miss any of these, and audits will shut you down fast.

Mass customization at scale (consumer products, orthotics, dental, wearables)

Beyond the certified parts world, another production category exploded: mass customization. Every single unit can be unique without touching a mold or swapping dies. AM lets you personalize at scale. Each print, different from the last.You need this pipeline: parametric CAD, automated quoting, and intelligent batching logic. That’s how customization becomes profitable instead of chaotic.

Low-volume and bridge production that protects timelines

Customization isn’t the only volume sweet spot. AM crushes it when you need 50 to 10,000 units yesterday whether as a permanent fix or a stopgap while tooling gets built.

3D printing for production regularly outperforms injection molding in these ranges, especially when geometry gets weird or when you’re still tweaking designs.Choose bridge versus permanent based on how volatile your product lifecycle is and how confident your forecasts are. Don’t reflexively default to molding when demand is fuzzy.

Tooling, jigs, fixtures, and factory aids (high ROI, fast adoption)

If you’re nervous about jumping straight into end-use parts, factory tooling and fixtures offer a smart, low-risk entry point with immediate returns that prove the case internally. Manufacturers deploy 3D printing in manufacturing for ergonomic fixtures, mistake-proofing guides, custom soft jaws, and inspection nests.Rank tooling candidates by downtime impact and how often they need revisions. Those deliver the fastest payback and build credibility with your team.

Technology breakthroughs that enabled 3D printing for production (beyond the printer)

These applications didn’t just happen, they became viable because of specific advances in materials, process discipline, finishing techniques, and software that most folks overlook.

Materials engineered for real-world performance

Production-grade polymers PA12, PA11, TPU, carbon-reinforced nylons hold up in harsh conditions. Metals like aluminum, titanium, and stainless steel are mainstream now, though you’ve got to watch for porosity, warping, and support mark issues.Match your materials to the environment: heat cycles, fatigue loading, chemical exposure, UV degradation, wear patterns. Never assume a material works just because it prints nicely.

Process control, repeatability, and statistical quality

Even killer materials fall flat without process rigor, repeatability and statistical control separate hobbyist shops from real manufacturers. The repeatability stack includes machine calibration schedules, parameter lockdown, powder lifecycle management, and standardized build orientation rules.Monitor first-pass yield, dimensional capability metrics, scrap rates, and rework hours. Those numbers tell you if your process is stable enough to call it production.

Post-processing as a production line (not an afterthought)

Dimensional consistency is just step one. Post-processing has to be treated as a core production stage not something you figure out later to hit finish and performance targets. Surface finishing spans bead blasting, dyeing, vapor smoothing, machining critical dimensions, heat treating metal parts, and protective coatings.

Lock down finish specs, early surface roughness targets, cosmetic zones, sealing requirements or rework loops will obliterate your margins.

Cost and volume reality check: the sweet spot vs injection molding and CNC

Technology puzzle solved. Now the question every manufacturer asks: when does the math actually work compared to injection molding or CNC machining?

Cost drivers for additive manufacturing production (transparent breakdown)

Material expense, machine runtime, labor, post-processing, QA/inspection, yield losses, and logistics all of it adds up. Build a per-part cost model with sensitivity scenarios for volume, part height, packing density, and finish requirements.Understanding individual line items matters, but real decisions pivot on break-even analysis that factors in complexity, design change frequency, and time-to-market value not just unit count. Factor in engineering change cost and speed-to-market value when calculating ROI.

Hybrid manufacturing strategies that win in the real world

Instead of forcing yourself into an either-or corner, the sharpest manufacturers blend AM with traditional methods to capture optimal economics at each lifecycle stage. Pair AM with CNC for critical surfaces, use AM tooling inserts in molds, or print parts as a bridge then transition to injection molds once volumes justify it.A staged approach reduces risk and keeps your options open as volumes climb.

Your Questions About Production 3D Printing, Answered

Can 3D printing be used for mass production at scale?

Absolutely, though mass is relative. For parts with intricate features, customization requirements, or volumes below 10,000 units, AM frequently wins on economics versus traditional manufacturing.

Which 3D printing processes are best for production?

SLS and MJF dominate functional polymers, SLA excels for high-detail work, and DMLS/SLM own the metal space. Each process shines in different scenarios based on material properties and surface finish demands.

How do I ensure consistency between batches and across multiple printers?

Lock down parameters, standardize part orientation, manage powder lifecycle carefully, and run validation builds with documented inspection protocols. Track dimensional capability and first-pass yield relentlessly.

Final Thoughts on the Production Shift

3D printing in manufacturing has come a long way from prototyping-only status. The technology delivers genuine production value when you select appropriate applications, maintain tight process control, and design parts with additive constraints in mind. Start with high-impact use cases tooling, spare parts, or low-volume end-use components then expand as your confidence and capability mature. The companies winning today treat AM as a legitimate production system, not a novelty tool. If you’re still limiting yourself to prototypes only, you’re leaving speed advantages, design flexibility, and real cost savings sitting on the table untouched.