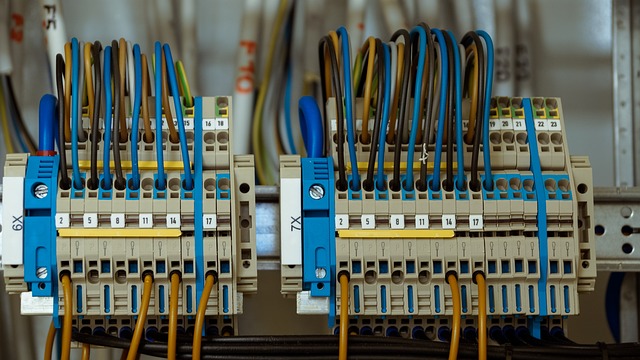

Custom cable harnesses are critical components in modern electronics. They may not always be visible, but their importance must be balanced. These intricate assemblies of wires, connectors, and terminals are essential for organizing and protecting electrical systems.

It ensures seamless operation across a wide range of applications. From automotive and aerospace to consumer electronics and industrial machinery, a custom wire harness is the backbone of modern electronics.

The Role of Custom Harnesses in Various Industries

These are indispensable in numerous industries, each with unique requirements that dictate the design and functionality of these components.

- Automotive Industry: In the automotive sector, custom straps are designed to handle specific power and data distribution needs. They are engineered to withstand harsh conditions, including extreme temperatures, vibrations, and chemical exposure. With the rise of electric vehicles, their complexity and importance have increased significantly, enabling the integration of advanced technologies such as autonomous driving systems and infotainment features.

- Aerospace and Aviation: Due to the critical nature of its applications, the aerospace industry demands exceptionally reliable and durable straps. These must perform flawlessly under extreme conditions, including high altitudes, temperature fluctuations, and intense vibrations. The quality and precision of these custom components depend heavily on ensuring the safety and reliability of aircraft systems.

- Consumer Electronics: Custom straps are crucial in managing power and data connections within compact and complex devices. From smartphones and laptops to home appliances, these ensure that electronic components communicate effectively and function reliably. The miniaturization of electronics has led to increasingly intricate designs for harnesses, demanding higher precision and quality.

- Industrial Machinery: Custom straps are vital in industrial machinery, facilitating the efficient operation of equipment and systems. These must endure harsh environments, such as dust, moisture, and mechanical stress exposure. Their reliability and durability are essential for maintaining the productivity and safety of industrial operations.

Advancements in Harness Technology

The continuous evolution of technology drives advancements in custom strap manufacturing. Innovations in materials, manufacturing processes, and design tools have significantly improved these straps’ performance, reliability, and efficiency.

- Material Innovations: The development of new, high-performance materials has enhanced harnesses’ durability and flexibility. Advanced thermoplastic and thermoset compounds offer improved resistance to environmental stressors such as heat, cold, and moisture. These materials extend harnesses’ lifespans and reduce their overall weight, which is particularly beneficial in the automotive and aerospace industries.

- Precision Manufacturing: Technological advancements, including automation and precision engineering, have revolutionized strap production. Automated cutting, stripping, and crimping processes increase the speed and accuracy of assembly, minimizing human error and optimizing production time. Precision manufacturing is critical in applications where even a minor mistake can have significant consequences.

- Design Software: Cutting-edge software tools enable meticulous harness design and testing before production. These tools allow engineers to create virtual prototypes, perform simulations, and optimize designs for performance and manufacturability. Rapid prototyping and virtual testing reduce the time and cost of bringing new products to market, ensuring that harnesses meet stringent quality standards.

Environmental and Economic Impact

As industries prioritize sustainability, custom harness manufacturing is evolving to minimize its environmental footprint. Efforts to reduce waste, improve energy efficiency, and use recyclable materials are becoming increasingly important.

- Recyclable Materials: Manufacturers are incorporating recyclable materials into harness production to reduce waste and promote sustainability. Using materials that can be easily recycled or repurposed helps lower the environmental impact of manufacturing processes and supports the circular economy.

- Energy Efficiency: Improving the energy efficiency of harnesses contributes to the overall energy savings of the devices in which they are used. Manufacturers can create greener technology solutions that align with global sustainability goals by reducing energy consumption. Enhanced energy efficiency also leads to cost savings for end-users, making products more attractive.

- Reduction in Waste: Modern manufacturing processes are designed to minimize waste through more accurate wire cutting, better recycling practices, and reduced use of hazardous materials. These efforts not only comply with environmental regulations but also improve the efficiency and cost-effectiveness of production lines.

A custom wire harness is the unsung hero of modern electronics, providing the backbone for various technological advancements. Their role in ensuring electronic systems’ functionality, reliability, and efficiency across multiple industries cannot be overstated. The demand for highly specialized and efficient wire harness solutions will increase as technology evolves rapidly. The industry’s commitment to innovation, quality, and sustainability ensures that it remains at the forefront of technological development, ready to meet the challenges of tomorrow. By continuously improving and adapting, these manufacturers play a pivotal role in wiring the future of technology, making possible the next generation of innovations.